Quality Standard & Acceptable Level

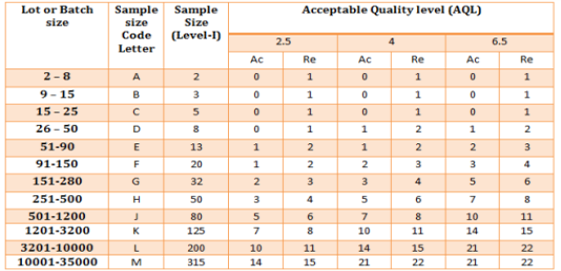

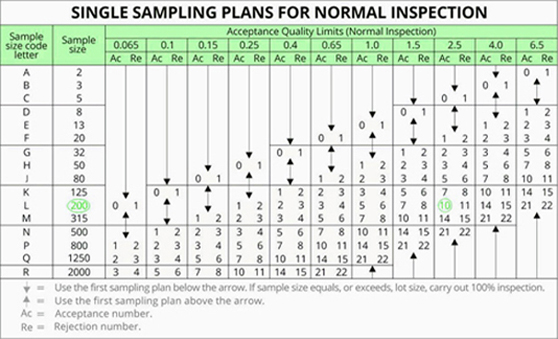

Maxserve uses international standards ANSI/ASQ Z1.4-2008 (AQL) for inspections. This standard is for acceptable level of Quality under the sample lots from the production. This method is widely used to decide whether to accept a production lot without checking every single item. It offers the advantage of clearly Defining the number of sample lots to be inspected from a given consignment. it also suggests the maximum number of defective items allowed in the sample lot size unless specified by the clients.

Standard AQL Level

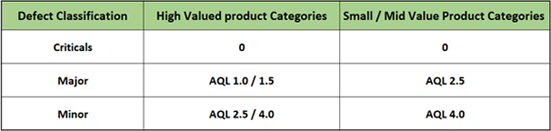

Below are the defect Classification.

Critical - these defects not allowed on acceptable limits, its refer to a defect which is unsafe for consumers.

Major - these defects refer to the product which not as per the standard or requirment as per the product descriptions. we follow 2.5 AQL for Major defects.

Minor - these defects not effect the look or stability of products but is beyond the defined quality standard and may reduce the salability of of the products. we follow 4.0 AQL for minor defcts.

Other then this clients can also specify the what points are minor, major or Critical in their own Checklist.